|

Tanker Vessel

|

Type

|

Capacity (Dwt)

|

Built

|

Shipyard

|

Delivered

|

Scrubber

|

Details

|

|---|---|---|---|---|---|---|---|

|

Freeport Star

|

Aframax

|

115,062

|

Mar. 2023

|

DHSC, S. Korea

|

|

|

|

|

Stavanger Star

|

LR2

|

114,940

|

Feb. 2025

|

DHSC, S. Korea

|

|

|

|

|

Oslo Star

|

LR2

|

114,940

|

Mar. 2025

|

DHSC, S. Korea

|

|

|

|

|

Copenhagen Star

|

LR2

|

114,940

|

May. 2025

|

DHSC, S. Korea

|

|

|

|

|

Athenian Star

|

LR2

|

114,940

|

Jun. 2025

|

DHSC, S. Korea

|

|

|

|

|

Geneva Star

|

Suezmax

|

157,000

|

Oct. 2025

|

DHSC, S. Korea

|

|

|

|

|

HN5101 (TBN Lausanne Star)

|

Suezmax

|

157,000

|

Nov. 2025

|

DHSC, S. Korea

|

|

|

|

|

HN5102 (TBN North Star)

|

Suezmax

|

157,000

|

Dec. 2025

|

DHSC, S. Korea

|

|

|

|

|

HN5103 (TBN Viking Star)

|

Suezmax

|

157,000

|

Jan. 2026

|

DHSC, S. Korea

|

|

|

|

|

HN5107 (TBN Artic Star)

|

Suezmax

|

157,000

|

May. 2026

|

DHSC, S. Korea

|

|

|

|

|

HN5108 (TBN Tromso Star)

|

Suezmax

|

157,000

|

Jul. 2026

|

DHSC, S. Korea

|

|

|

|

|

HN5109 (TBN ODIN STAR)

|

Suezmax

|

157,000

|

Oct. 2026

|

DHSC, S. Korea

|

|

|

|

|

HN5111 (TBN OLYMPIC STAR)

|

Suezmax

|

157,000

|

Mar. 2027

|

DHSC, S. Korea

|

|

|

|

|

Total Tanker Fleet (Dwt)

|

|

1,830,822

|

|

|

|

|

|

|

PCTC Vessel

|

Type

|

Capacity (ceu)

|

Built

|

Shipyard

|

Delivered

|

Details

|

|---|---|---|---|---|---|---|

|

UGR AL SAMHA (3rd party ownership)

|

DF LNG PCTC

|

7,000

|

Mar. 2025

|

CIMC Raffles, China

|

|

|

|

UGR ZAKHER (3rd party ownership)

|

DF LNG PCTC

|

7,000

|

May. 2025

|

CIMC Raffles, China

|

|

|

|

HN H580 (TBN Eco Star)

|

DF LNG PCTC

|

7,000

|

Mar. 2026

|

CIMC Raffles, China

|

|

|

|

HN H591 (TBN Clean Star)

|

DF LNG PCTC

|

7,000

|

Jul. 2026

|

CIMC Raffles, China

|

|

|

|

Total PCTC Fleet (ceu)

|

|

28,000

|

|

|

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

230 m

|

|

Breadth, molded

|

32.25 m

|

|

Depth, molded:

|

23.85 m

|

|

Design draft, molded:

|

11.75 m

|

|

Scantling draft, molded:

|

13.65 m

|

|

Deadweight @ Scantling Draft

|

51,641 MT

|

|

Service speed:

|

16,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

HYUNDAI-MAN B&W 6G60ME-C10.5-LGIP-HPSCR with EEC function

|

|

MCR

|

12,810 kW at 94,5 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,760 kWe each

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Composite Boiler

|

3 ton/h (oil fired

|

|

0.85 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

5,300 Nm3/h

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

* Commercial Butane (normal and iso-butane mixed in any proportion)

* Pure Propane * Commercial Propane (maximum 8.0 mole % ethane in the liquid phase) * Mixture of Propane and Butane in any proportion *Propylene *Anhydrous Ammonia |

|

No. of cargo tanks

|

Four (4)- No.4 cargo tank to be used as LPG fuel tank

|

|

Cargo tanks capacity

|

approx. 88,000 ㎥ (at 100%)

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Deepwell pumps of vertical, centrifugal, multistage design

|

|

Specification

|

8 x 600 ㎥/h

|

|

Booster Pumps

|

2 x 600 ㎥/h

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 650 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

Hyundai HiBallast

|

Premium quality, non filter, 3,600 m3/h, IMO & USCG approved

|

|

DECK CRANE

|

|

|---|---|

|

1 x Hose handling crane

|

10 MT / Personel Lifting Certified

|

|

2 x Provisions handling crane

|

4 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo tanks insulation

|

Spray foam insulation with a polymeric surface protection coating

|

|

WB tanks

|

Full Epoxy

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

IE2 high efficiency motors for essential pumps, Variable Frequency Drives for LP and HP LPG and main CSW pumps, Ultra Low Friction Biotechnology Antifouling, HD Hyundai ISS Intergated Smart Ship Solution, HiNAS Hyundai intelligent Navigation Assistant System, EEC Economizer Energy Control System

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF Mooring Equipment Guidelines [MEG4]

|

|

|

- NOx TIER III

|

|

|

- Energy Efficiency Design Index [EEDI] PHASE III

|

|

|

- Stern Tube AIR SEALS

|

|

|

- CCTV system

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 274,0 m

|

|

Breadth, molded

|

48 m

|

|

Depth, molded:

|

23.6 m

|

|

Design draft, molded:

|

16.0 m

|

|

Scantling draft, molded:

|

17.2 m

|

|

Deadweight at Ts:

|

157K

|

|

Service speed:

|

14,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G70ME-C10.5 (Tier III)

|

|

MCR

|

13,340 kW at 66.6 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,300kW at 900 rpm

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 30 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.55 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

13,200 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Crude Oil

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 173,600 ㎥

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Available

|

|

SCRUBBER Fitted

|

|

|---|---|

|

Scubber System

|

U type, Open Loop

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 2,000 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

BWTS

|

4,000 m3/h

|

|

DECK CRANE

|

|

|---|---|

|

2 x Cargo hose handling crane

|

Each 20 MT

Personel Lifting Certified |

|

2 x Provisions handling crane

|

8 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Partially Coated / 2 x Epoxy anti-corrosive

|

|

WB tanks

|

Fully Coated / 2 x Epoxy anti-corrosive

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Mewis Duct and a twisted full spade rudder with bulb shall be installed for the improvement of propulsion efficiency

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE III

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

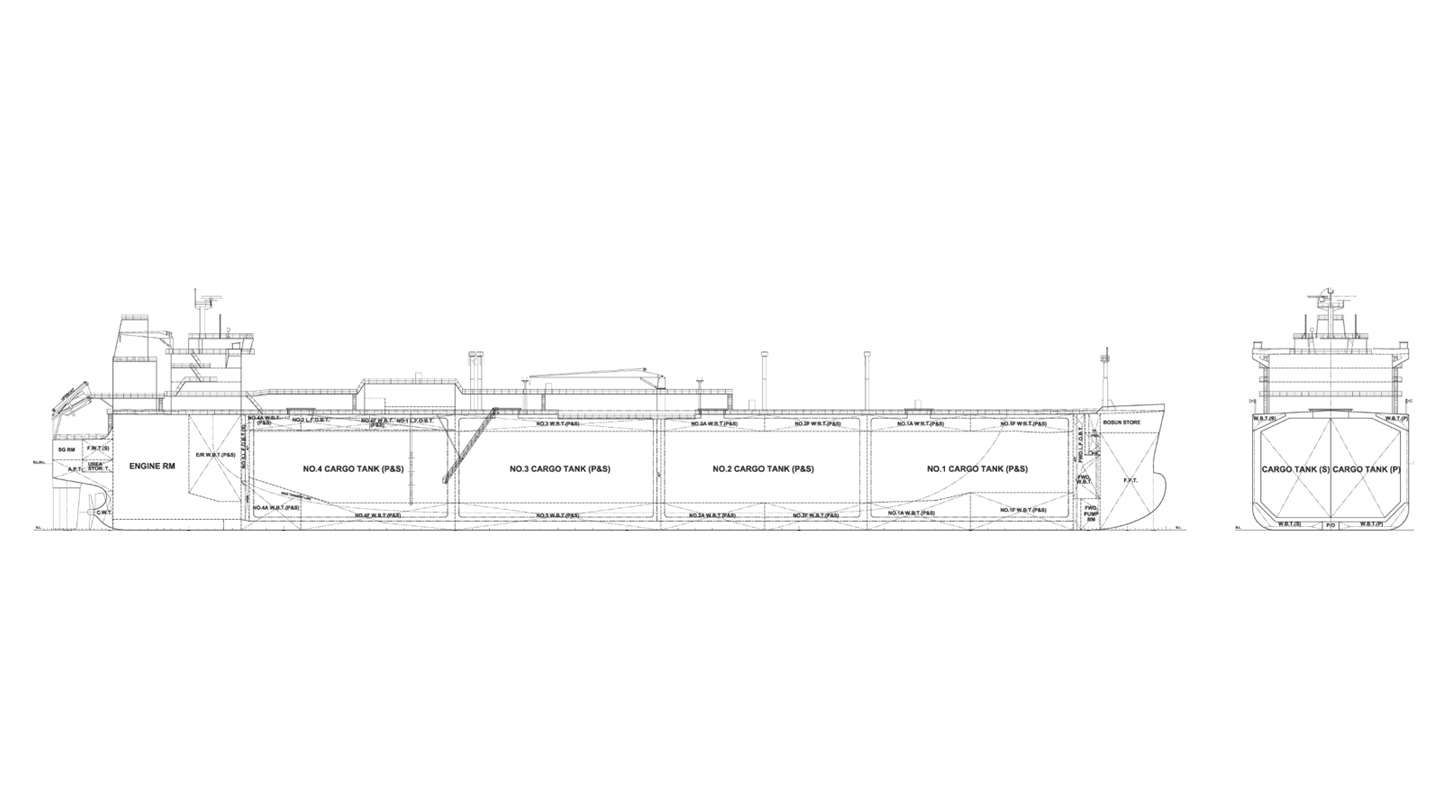

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 249.9 m

|

|

Breadth, molded

|

44 m

|

|

Depth, molded:

|

21.2 m

|

|

Design draft, molded:

|

13.6 m

|

|

Scantling draft, molded:

|

15.2 m

|

|

Deadweight at Ts:

|

115,062 MT

|

|

Service speed:

|

14 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G60ME-C10.5 (Tier III, EGR + BP)

|

|

MCR

|

13,000 kW at 86.0 rpm

|

|

Latest version of Electronic G-Type Engine with reduced SFOC, design optimized components, TRITON Control Platform

|

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

6L23/30H Mk 3 (LPSCR - BP) Each 1,140 kWe

|

|

Latest version EcoGen of inovative technology and fully 2020 sulphur cap compliant with reduced SFOC and modern safety & control system by MAN SaCoSone

|

|

|

BOILERS

|

|

|---|---|

|

2 - Auxiliary boiler:

|

Each 25 ton/h

|

|

1 - Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.85 ton/h (exhaust gas)

|

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Crude oil

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 130,100 ㎥

|

|

CARGO PUMP

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Stainless Steel 316L Heating coils

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 1,800 m3/h x 35 mTH

|

|

BWTS

|

USCG Approved

Indirect electrolysis type, 3,600 ㎥/h |

|

DECK CRANE

|

|

|---|---|

|

2 - Cargo hose handling crane

|

Each 15 MT

Personel Lifting Certified |

|

2 - Provisions handling crane

|

4 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo tanks

|

Partly Coated Epoxy A/C

|

|

WB tanks

|

Epoxy A/C

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Full spade rudder with twisted leading edge & a rudder bulb and DSME duct

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE II

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

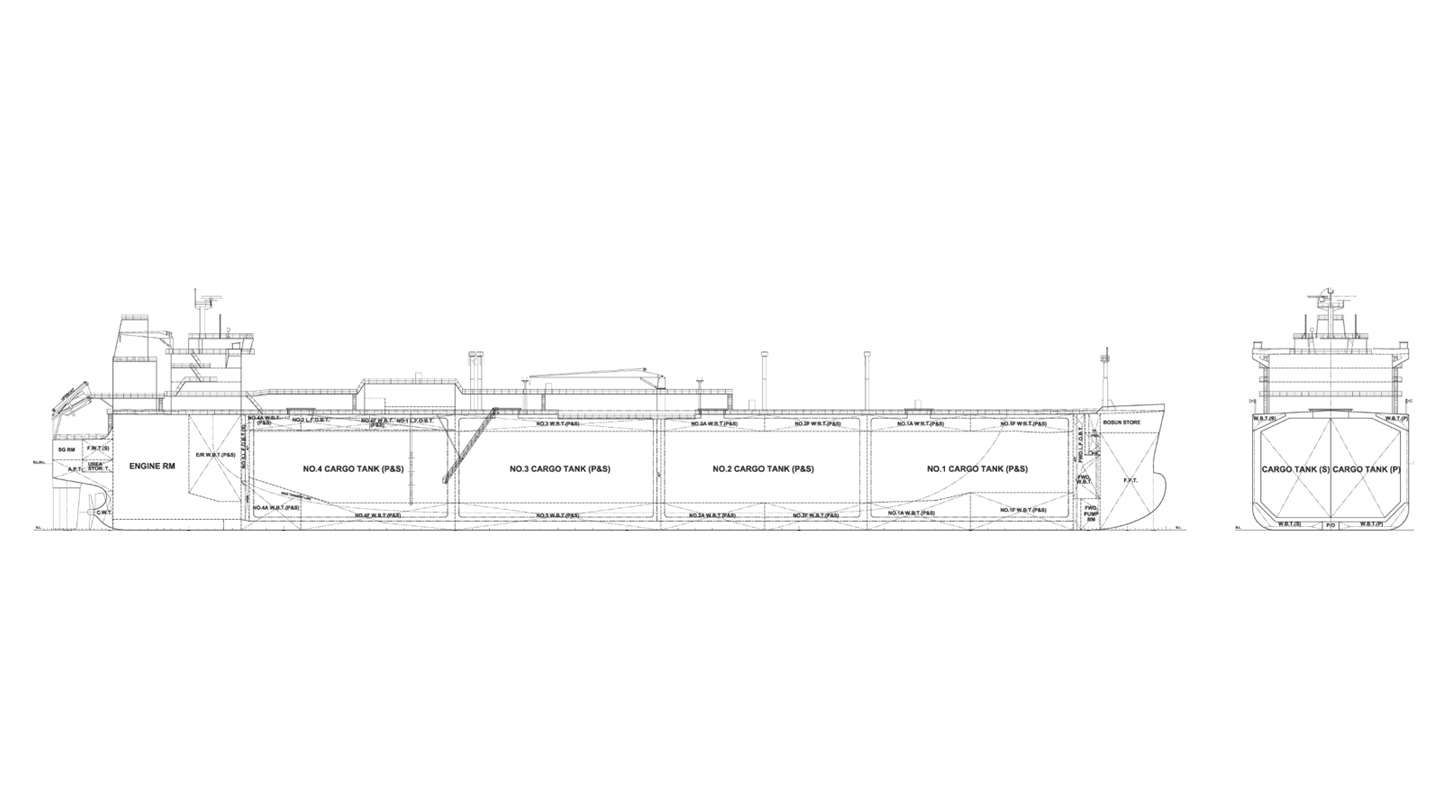

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 249.9 m

|

|

Breadth, molded

|

44 m

|

|

Depth, molded:

|

21.2 m

|

|

Design draft, molded:

|

13.6 m

|

|

Scantling draft, molded:

|

15.2 m

|

|

Deadweight at Ts:

|

115,062 MT

|

|

Service speed:

|

14 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G60ME-C10.5 (Tier III, EGR)

|

|

MCR

|

13,000 kW at 86.0 rpm

|

|

Latest version of Electronic G-Type Engine with reduced SFOC, design optimized components, TRITON Control Platform

|

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 6L23/30H Mk 3 (LPSCR - BP) of 1,140 kWe each

|

|

Latest version EcoGen of inovative technology and fully 2020 sulphur cap compliant with reduced SFOC and modern safety & control system by MAN SaCoSone

|

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 25 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.85 ton/h (exhaust gas)

|

|

|

Inert Gas Generator

|

11,250 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Oil Product Carrier [LR2]

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 129,000 ㎥

|

|

CARGO PUMP

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Stainless Steel 316L Heating coils

|

|

SCRUBBER Fitted

|

|

|---|---|

|

MS - Sox

|

U type, Open Loop, Titanium body, 0.1%S complaiant

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 1,800 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

Huyndai HiBallast

|

Premium quality, non filter, 3,600 m3/h, IMO & USCG approved

|

|

DECK CRANE

|

|

|---|---|

|

2 - Cargo hose handling crane

|

Each 15 MT

Personel Lifting Certified |

|

2 - Provisions handling crane

|

4 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Fully Epoxy A/C coated

|

|

Residual Tank

|

|

|

WB tanks

|

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Full spade rudder with twisted leading edge, rudder bulb, DSME duct, VLDs, and Intelligent Cooling Water Energy System

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE II

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

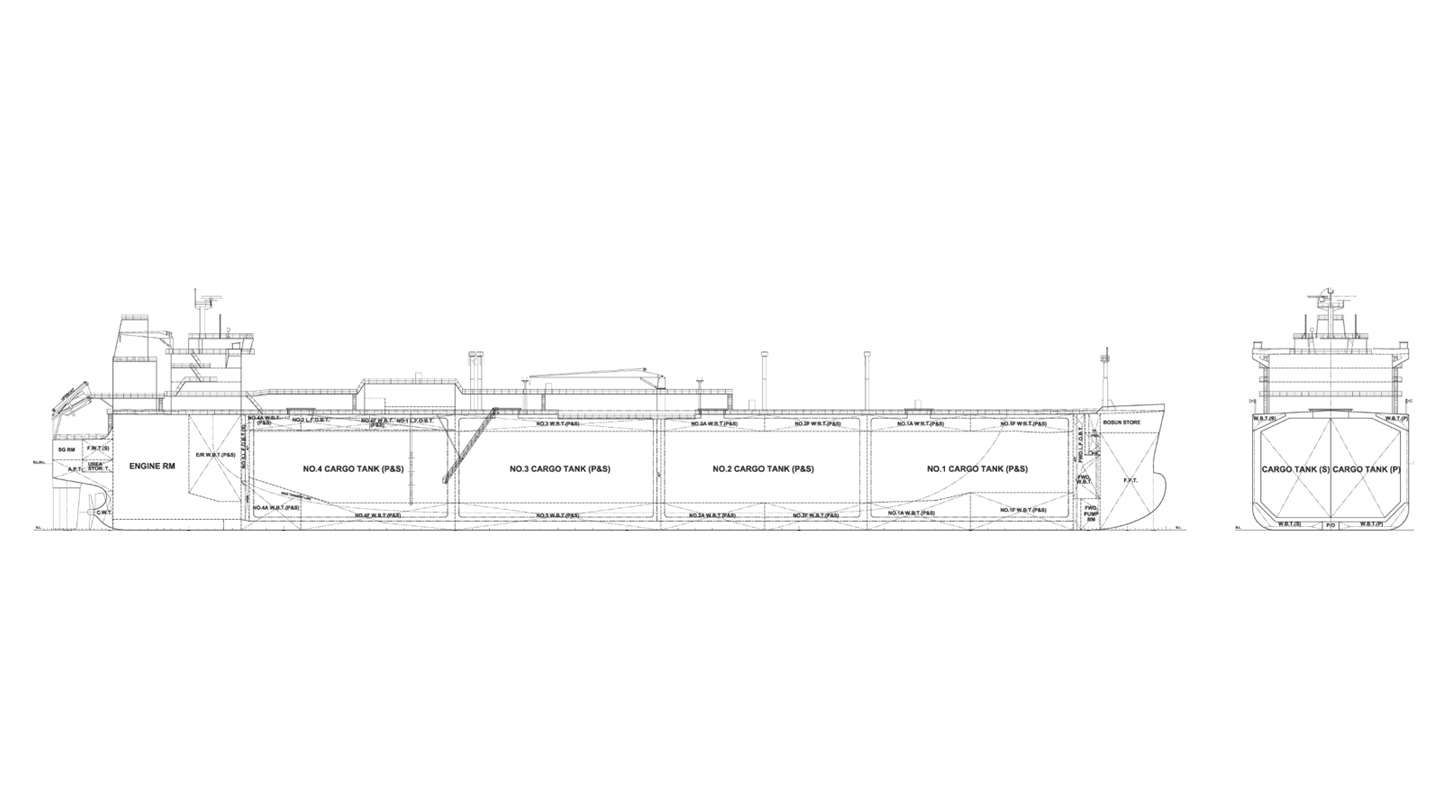

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 249.9 m

|

|

Breadth, molded

|

44 m

|

|

Depth, molded:

|

21.2 m

|

|

Design draft, molded:

|

13.6 m

|

|

Scantling draft, molded:

|

15.2 m

|

|

Deadweight at Ts:

|

115,062 MT

|

|

Service speed:

|

14 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G60ME-C10.5 (Tier III, EGR)

|

|

MCR

|

13,000 kW at 86.0 rpm

|

|

Latest version of Electronic G-Type Engine with reduced SFOC, design optimized components, TRITON Control Platform

|

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 6L23/30H Mk 3 (LPSCR - BP) of 1,140 kWe each

|

|

Latest version EcoGen of inovative technology and fully 2020 sulphur cap compliant with reduced SFOC and modern safety & control system by MAN SaCoSone

|

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 25 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.85 ton/h (exhaust gas)

|

|

|

Inert Gas Generator

|

11,250 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Oil Product Carrier [LR2]

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 129,000 ㎥

|

|

CARGO PUMP

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Stainless Steel 316L Heating coils

|

|

SCRUBBER Fitted

|

|

|---|---|

|

MS - Sox

|

U type, Open Loop, Titanium body, 0.1%S complaiant

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 1,800 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

Huyndai HiBallast

|

Premium quality, non filter, 3,600 m3/h, IMO & USCG approved

|

|

DECK CRANE

|

|

|---|---|

|

2 - Cargo hose handling crane

|

Each 15 MT

Personel Lifting Certified |

|

2 - Provisions handling crane

|

4 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Fully Epoxy A/C coated

|

|

Residual Tank

|

|

|

WB tanks

|

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Full spade rudder with twisted leading edge, rudder bulb, DSME duct, VLDs, and Intelligent Cooling Water Energy System

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE II

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 249.9 m

|

|

Breadth, molded

|

44 m

|

|

Depth, molded:

|

21.2 m

|

|

Design draft, molded:

|

13.6 m

|

|

Scantling draft, molded:

|

15.2 m

|

|

Deadweight at Ts:

|

115,062 MT

|

|

Service speed:

|

14 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G60ME-C10.5 (Tier III, EGR)

|

|

MCR

|

13,000 kW at 86.0 rpm

|

|

Latest version of Electronic G-Type Engine with reduced SFOC, design optimized components, TRITON Control Platform

|

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 6L23/30H Mk 3 (LPSCR - BP) of 1,140 kWe each

|

|

Latest version EcoGen of inovative technology and fully 2020 sulphur cap compliant with reduced SFOC and modern safety & control system by MAN SaCoSone

|

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 25 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.85 ton/h (exhaust gas)

|

|

|

Inert Gas Generator

|

11,250 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Oil Product Carrier [LR2]

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 129,000 ㎥

|

|

CARGO PUMP

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Stainless Steel 316L Heating coils

|

|

SCRUBBER Fitted

|

|

|---|---|

|

MS - Sox

|

U type, Open Loop, Titanium body, 0.1%S complaiant

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 1,800 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

Huyndai HiBallast

|

Premium quality, non filter, 3,600 m3/h, IMO & USCG approved

|

|

DECK CRANE

|

|

|---|---|

|

2 - Cargo hose handling crane

|

Each 15 MT

Personel Lifting Certified |

|

2 - Provisions handling crane

|

4 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Fully Epoxy A/C coated

|

|

Residual Tank

|

|

|

WB tanks

|

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Full spade rudder with twisted leading edge, rudder bulb, DSME duct, VLDs, and Intelligent Cooling Water Energy System

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE II

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 249.9 m

|

|

Breadth, molded

|

44 m

|

|

Depth, molded:

|

21.2 m

|

|

Design draft, molded:

|

13.6 m

|

|

Scantling draft, molded:

|

15.2 m

|

|

Deadweight at Ts:

|

115,062 MT

|

|

Service speed:

|

14 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G60ME-C10.5 (Tier III, EGR)

|

|

MCR

|

13,000 kW at 86.0 rpm

|

|

Latest version of Electronic G-Type Engine with reduced SFOC, design optimized components, TRITON Control Platform

|

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 6L23/30H Mk 3 (LPSCR - BP) of 1,140 kWe each

|

|

Latest version EcoGen of inovative technology and fully 2020 sulphur cap compliant with reduced SFOC and modern safety & control system by MAN SaCoSone

|

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 25 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.85 ton/h (exhaust gas)

|

|

|

Inert Gas Generator

|

11,250 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Oil Product Carrier [LR2]

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 129,000 ㎥

|

|

CARGO PUMP

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Stainless Steel 316L Heating coils

|

|

SCRUBBER Fitted

|

|

|---|---|

|

MS - Sox

|

U type, Open Loop, Titanium body, 0.1%S complaiant

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 1,800 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

Huyndai HiBallast

|

Premium quality, non filter, 3,600 m3/h, IMO & USCG approved

|

|

DECK CRANE

|

|

|---|---|

|

2 - Cargo hose handling crane

|

Each 15 MT

Personel Lifting Certified |

|

2 - Provisions handling crane

|

4 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Fully Epoxy A/C coated

|

|

Residual Tank

|

|

|

WB tanks

|

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Full spade rudder with twisted leading edge, rudder bulb, DSME duct, VLDs, and Intelligent Cooling Water Energy System

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE II

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

230 m

|

|

Breadth, molded

|

32.25 m

|

|

Depth, molded:

|

23.85 m

|

|

Design draft, molded:

|

11.75 m

|

|

Scantling draft, molded:

|

13.65 m

|

|

Deadweight @ Scantling Draft

|

51,641 MT

|

|

Service speed:

|

16,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

HYUNDAI-MAN B&W 6G60ME-C10.5-LGIP-HPSCR with EEC function

|

|

MCR

|

12,810 kW at 94,5 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,760 kWe each

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Composite Boiler

|

3 ton/h (oil fired

|

|

0.85 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

5,300 Nm3/h

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

* Commercial Butane (normal and iso-butane mixed in any proportion)

* Pure Propane * Commercial Propane (maximum 8.0 mole % ethane in the liquid phase) * Mixture of Propane and Butane in any proportion *Propylene *Anhydrous Ammonia |

|

No. of cargo tanks

|

Four (4)- No.4 cargo tank to be used as LPG fuel tank

|

|

Cargo tanks capacity

|

approx. 88,000 ㎥ (at 100%)

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Deepwell pumps of vertical, centrifugal, multistage design

|

|

Specification

|

8 x 600 ㎥/h

|

|

Booster Pumps

|

2 x 600 ㎥/h

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 650 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

Hyundai HiBallast

|

Premium quality, non filter, 3,600 m3/h, IMO & USCG approved

|

|

DECK CRANE

|

|

|---|---|

|

1 x Hose handling crane

|

10 MT / Personel Lifting Certified

|

|

2 x Provisions handling crane

|

4 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo tanks insulation

|

Spray foam insulation with a polymeric surface protection coating

|

|

WB tanks

|

Full Epoxy

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

IE2 high efficiency motors for essential pumps, Variable Frequency Drives for LP and HP LPG and main CSW pumps, Ultra Low Friction Biotechnology Antifouling, HD Hyundai ISS Intergated Smart Ship Solution, HiNAS Hyundai intelligent Navigation Assistant System, EEC Economizer Energy Control System

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF Mooring Equipment Guidelines [MEG4]

|

|

|

- NOx TIER III

|

|

|

- Energy Efficiency Design Index [EEDI] PHASE III

|

|

|

- Stern Tube AIR SEALS

|

|

|

- CCTV system

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 274,0 m

|

|

Breadth, molded

|

48 m

|

|

Depth, molded:

|

23.6 m

|

|

Design draft, molded:

|

16.0 m

|

|

Scantling draft, molded:

|

17.2 m

|

|

Deadweight at Ts:

|

157K

|

|

Service speed:

|

14,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G70ME-C10.5 (Tier III)

|

|

MCR

|

13,340 kW at 66.6 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,300kW at 900 rpm

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 30 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.55 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

13,200 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Crude Oil

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 173,600 ㎥

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Available

|

|

SCRUBBER Fitted

|

|

|---|---|

|

Scubber System

|

U type, Open Loop

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 2,000 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

BWTS

|

4,000 m3/h

|

|

DECK CRANE

|

|

|---|---|

|

2 x Cargo hose handling crane

|

Each 20 MT

Personel Lifting Certified |

|

2 x Provisions handling crane

|

8 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Partially Coated / 2 x Epoxy anti-corrosive

|

|

WB tanks

|

Fully Coated / 2 x Epoxy anti-corrosive

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Mewis Duct and a twisted full spade rudder with bulb shall be installed for the improvement of propulsion efficiency

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE III

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 274,0 m

|

|

Breadth, molded

|

48 m

|

|

Depth, molded:

|

23.6 m

|

|

Design draft, molded:

|

16.0 m

|

|

Scantling draft, molded:

|

17.2 m

|

|

Deadweight at Ts:

|

157K

|

|

Service speed:

|

14,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G70ME-C10.5 (Tier III)

|

|

MCR

|

13,340 kW at 66.6 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,300kW at 900 rpm

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 30 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.55 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

13,200 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Crude Oil

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 173,600 ㎥

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Available

|

|

SCRUBBER Fitted

|

|

|---|---|

|

Scubber System

|

U type, Open Loop

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 2,000 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

BWTS

|

4,000 m3/h

|

|

DECK CRANE

|

|

|---|---|

|

2 x Cargo hose handling crane

|

Each 20 MT

Personel Lifting Certified |

|

2 x Provisions handling crane

|

8 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Partially Coated / 2 x Epoxy anti-corrosive

|

|

WB tanks

|

Fully Coated / 2 x Epoxy anti-corrosive

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Mewis Duct and a twisted full spade rudder with bulb shall be installed for the improvement of propulsion efficiency

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE III

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 274,0 m

|

|

Breadth, molded

|

48 m

|

|

Depth, molded:

|

23.6 m

|

|

Design draft, molded:

|

16.0 m

|

|

Scantling draft, molded:

|

17.2 m

|

|

Deadweight at Ts:

|

157K

|

|

Service speed:

|

14,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G70ME-C10.5 (Tier III)

|

|

MCR

|

13,340 kW at 66.6 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,300kW at 900 rpm

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 30 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.55 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

13,200 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Crude Oil

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 173,600 ㎥

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Available

|

|

SCRUBBER Fitted

|

|

|---|---|

|

Scubber System

|

U type, Open Loop

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 2,000 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

BWTS

|

4,000 m3/h

|

|

DECK CRANE

|

|

|---|---|

|

2 x Cargo hose handling crane

|

Each 20 MT

Personel Lifting Certified |

|

2 x Provisions handling crane

|

8 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Partially Coated / 2 x Epoxy anti-corrosive

|

|

WB tanks

|

Fully Coated / 2 x Epoxy anti-corrosive

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Mewis Duct and a twisted full spade rudder with bulb shall be installed for the improvement of propulsion efficiency

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE III

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

KEY FEATURES

|

|

|---|---|

|

- NOx Tier II: M/E with EGR, A/E on gas mode & SCR * Adaptable for STS LNG bunkering

|

|

|

- Hull form features SDARI S-BOW - Optimized car flew efficiency

|

|

|

- BEVs and hydrogen-fueled vehicles (FCEVs) carded - IMDG packaged cargo on deck 5

|

|

|

- Shore connection for zero emission in port

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

abt. 199.90 m

|

|

Length between perp.

|

195.60 m

|

|

Breadth moulded

|

38.00 m

|

|

Depth moulded (to main deck)

|

14.80 m

|

|

Depth moulded (to upper deck)

|

abt. 36.58 m

|

|

Design draught (Td)

|

8.60 m

|

|

Scantling draught (Ts)

|

10.00 m

|

|

Air draught (from BWL)

|

max. 38.00 m

|

|

Deadweight Td

|

10.800 t

|

|

Deadweight @ Ts

|

18,500 t

|

|

Gross tonnage

|

69.000

|

|

Complement

|

25 P

|

|

TANK CAPACITIES

|

|

|---|---|

|

LNG {2 Type C tanks)

|

2x 1,650 m3

|

|

MGO

|

1.700 m3

|

|

Fresh/Drinktng wafer

|

460 m3

|

|

Water ballast

|

7000 m3

|

|

Endurance @ gas mode

19kn. ME+1xAE. fill. ratio 90%. LCV 50,000 kJ/kg. 5% reserve) |

12,500 n.m

|

|

Endurance @ diesel mode

(19kn, ME+1 xAE. fill. ratio 98%, LCV 42.700kJ/kg) |

11,500 n.m

|

|

MACHINERY MAIN COMPONENTS

|

|

|---|---|

|

Main engine

|

MAN 6S60ME-C10.5-GI-EcoEGR, Mk.2

|

|

NMCR

|

14.940 kW X 105 r/min

|

|

SMCR

|

13.300 kW x99 r/min

|

|

NCR

|

11.305 kWx 93.8 r/min

|

|

Propeller

|

1 X FPP

|

|

FGSS

|

High pressure type

|

|

DF generators

|

3 X 1,500 kWe

|

|

Bow thruster

|

1 X 1.800 kW, CPP

|

|

CARGO CAPACITY & EQUIPMENT

|

|

|---|---|

|

Car deck effective area

|

59,000 m2

|

|

Car capacity {Corona RT-43L)

|

approx. 7,000 CEU

|

|

No. of car decks

|

12

|

|

No. of liftable decks (DK 2.4. e. 8)

|

4

|

|

CAR DECK LOAD

|

||||

|---|---|---|---|---|

|

|

|

|

Med. deck

|

Light deck

|

|

Axle load

|

t/wheel No.

|

45/2, 55/4

|

5/2, 25/4

|

1.6/2

|

|

UDL

|

t/m2

|

3.0

|

2.0

|

0.26/0.3

|

|

Quarter stem ramp/door

|

150 τ

|

|---|---|

|

Side ramp/door

|

20 t

|

|

Ro-Ro equipment

|

Electrical Driven Type

|

|

ENERGY EFFICENCY PARTICULARS

|

|

|---|---|

|

Service speed @ Td

(NCR, Bft,0/DSS0. with 15% Sea Margin) |

19.0 knots

|

|

ECO speed @ Td

|

16.0 knots

|

|

Energy Saving Solutions

|

||||

|---|---|---|---|---|

|

* Twisted rudder + Fan Cap + Fan Duct

|

||||

|

* Self-polishing A/F paint

|

||||

|

* VFD control for cool. S.W. pumps, E/R vent, fans

|

||||

|

M/E Fuel Consumption @Td, NCR (15% S M. included)

|

||||

|---|---|---|---|---|

|

|

DF6C(t/d)

|

DFPC(t/d)

|

DFCOC(t/d)

|

|

|

Tier II

|

36.2

|

0.00

|

43.2

|

|

|

Tier III

|

37.2

|

0.00

|

44.3

|

|

|

(LCV LNG 50,000 kJ/kg. MGO 42,700 kJ/kg. , ISO cond., excl. tol)

|

||||

|

CLASSIFICATION

|

|

|---|---|

|

DNV

|

+ 1A, Car Carrier, Gas fuelled LNG, Fuel ready(Ammonia, D), MCDK, COAT-PSPC (B), E0, NAUT(OC), BIS, BWMC(T). DG(P), TMON(Oil lubricated), LCS, Recyclable, ER (EGR, Tier III), Shore power

|

|

EEDI

|

IMO Phase 2

|

|

KEY FEATURES

|

|

|---|---|

|

- NOx Tier II: M/E with EGR, A/E on gas mode & SCR * Adaptable for STS LNG bunkering

|

|

|

- Hull form features SDARI S-BOW - Optimized car flew efficiency

|

|

|

- BEVs and hydrogen-fueled vehicles (FCEVs) carded - IMDG packaged cargo on deck 5

|

|

|

- Shore connection for zero emission in port

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

abt. 199.90 m

|

|

Length between perp.

|

195.60 m

|

|

Breadth moulded

|

38.00 m

|

|

Depth moulded (to main deck)

|

14.80 m

|

|

Depth moulded (to upper deck)

|

abt. 36.58 m

|

|

Design draught (Td)

|

8.60 m

|

|

Scantling draught (Ts)

|

10.00 m

|

|

Air draught (from BWL)

|

max. 38.00 m

|

|

Deadweight Td

|

10.800 t

|

|

Deadweight @ Ts

|

18,500 t

|

|

Gross tonnage

|

69.000

|

|

Complement

|

25 P

|

|

TANK CAPACITIES

|

|

|---|---|

|

LNG {2 Type C tanks)

|

2x 1,650 m3

|

|

MGO

|

1.700 m3

|

|

Fresh/Drinktng wafer

|

460 m3

|

|

Water ballast

|

7000 m3

|

|

Endurance @ gas mode

19kn. ME+1xAE. fill. ratio 90%. LCV 50,000 kJ/kg. 5% reserve) |

12,500 n.m

|

|

Endurance @ diesel mode

(19kn, ME+1 xAE. fill. ratio 98%, LCV 42.700kJ/kg) |

11,500 n.m

|

|

MACHINERY MAIN COMPONENTS

|

|

|---|---|

|

Main engine

|

MAN 6S60ME-C10.5-GI-EcoEGR, Mk.2

|

|

NMCR

|

14.940 kW X 105 r/min

|

|

SMCR

|

13.300 kW x99 r/min

|

|

NCR

|

11.305 kWx 93.8 r/min

|

|

Propeller

|

1 X FPP

|

|

FGSS

|

High pressure type

|

|

DF generators

|

3 X 1,500 kWe

|

|

Bow thruster

|

1 X 1.800 kW, CPP

|

|

CARGO CAPACITY & EQUIPMENT

|

|

|---|---|

|

Car deck effective area

|

59,000 m2

|

|

Car capacity {Corona RT-43L)

|

approx. 7,000 CEU

|

|

No. of car decks

|

12

|

|

No. of liftable decks (DK 2.4. e. 8)

|

4

|

|

CAR DECK LOAD

|

||||

|---|---|---|---|---|

|

|

|

|

Med. deck

|

Light deck

|

|

Axle load

|

t/wheel No.

|

45/2, 55/4

|

5/2, 25/4

|

1.6/2

|

|

UDL

|

t/m2

|

3.0

|

2.0

|

0.26/0.3

|

|

Quarter stem ramp/door

|

150 τ

|

|---|---|

|

Side ramp/door

|

20 t

|

|

Ro-Ro equipment

|

Electrical Driven Type

|

|

ENERGY EFFICENCY PARTICULARS

|

|

|---|---|

|

Service speed @ Td

(NCR, Bft,0/DSS0. with 15% Sea Margin) |

19.0 knots

|

|

ECO speed @ Td

|

16.0 knots

|

|

Energy Saving Solutions

|

||||

|---|---|---|---|---|

|

* Twisted rudder + Fan Cap + Fan Duct

|

||||

|

* Self-polishing A/F paint

|

||||

|

* VFD control for cool. S.W. pumps, E/R vent, fans

|

||||

|

M/E Fuel Consumption @Td, NCR (15% S M. included)

|

||||

|---|---|---|---|---|

|

|

DF6C(t/d)

|

DFPC(t/d)

|

DFCOC(t/d)

|

|

|

Tier II

|

36.2

|

0.00

|

43.2

|

|

|

Tier III

|

37.2

|

0.00

|

44.3

|

|

|

(LCV LNG 50,000 kJ/kg. MGO 42,700 kJ/kg. , ISO cond., excl. tol)

|

||||

|

CLASSIFICATION

|

|

|---|---|

|

DNV

|

+ 1A, Car Carrier, Gas fuelled LNG, Fuel ready(Ammonia, D), MCDK, COAT-PSPC (B), E0, NAUT(OC), BIS, BWMC(T). DG(P), TMON(Oil lubricated), LCS, Recyclable, ER (EGR, Tier III), Shore power

|

|

EEDI

|

IMO Phase 2

|

|

KEY FEATURES

|

|

|---|---|

|

- NOx Tier II: M/E with EGR, A/E on gas mode & SCR * Adaptable for STS LNG bunkering

|

|

|

- Hull form features SDARI S-BOW - Optimized car flew efficiency

|

|

|

- BEVs and hydrogen-fueled vehicles (FCEVs) carded - IMDG packaged cargo on deck 5

|

|

|

- Shore connection for zero emission in port

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

abt. 199.90 m

|

|

Length between perp.

|

195.60 m

|

|

Breadth moulded

|

38.00 m

|

|

Depth moulded (to main deck)

|

14.80 m

|

|

Depth moulded (to upper deck)

|

abt. 36.58 m

|

|

Design draught (Td)

|

8.60 m

|

|

Scantling draught (Ts)

|

10.00 m

|

|

Air draught (from BWL)

|

max. 38.00 m

|

|

Deadweight Td

|

10.800 t

|

|

Deadweight @ Ts

|

18,500 t

|

|

Gross tonnage

|

69.000

|

|

Complement

|

25 P

|

|

TANK CAPACITIES

|

|

|---|---|

|

LNG {2 Type C tanks)

|

2x 1,650 m3

|

|

MGO

|

1.700 m3

|

|

Fresh/Drinktng wafer

|

460 m3

|

|

Water ballast

|

7000 m3

|

|

Endurance @ gas mode

19kn. ME+1xAE. fill. ratio 90%. LCV 50,000 kJ/kg. 5% reserve) |

12,500 n.m

|

|

Endurance @ diesel mode

(19kn, ME+1 xAE. fill. ratio 98%, LCV 42.700kJ/kg) |

11,500 n.m

|

|

MACHINERY MAIN COMPONENTS

|

|

|---|---|

|

Main engine

|

MAN 6S60ME-C10.5-GI-EcoEGR, Mk.2

|

|

NMCR

|

14.940 kW X 105 r/min

|

|

SMCR

|

13.300 kW x99 r/min

|

|

NCR

|

11.305 kWx 93.8 r/min

|

|

Propeller

|

1 X FPP

|

|

FGSS

|

High pressure type

|

|

DF generators

|

3 X 1,500 kWe

|

|

Bow thruster

|

1 X 1.800 kW, CPP

|

|

CARGO CAPACITY & EQUIPMENT

|

|

|---|---|

|

Car deck effective area

|

59,000 m2

|

|

Car capacity {Corona RT-43L)

|

approx. 7,000 CEU

|

|

No. of car decks

|

12

|

|

No. of liftable decks (DK 2.4. e. 8)

|

4

|

|

CAR DECK LOAD

|

||||

|---|---|---|---|---|

|

|

|

|

Med. deck

|

Light deck

|

|

Axle load

|

t/wheel No.

|

45/2, 55/4

|

5/2, 25/4

|

1.6/2

|

|

UDL

|

t/m2

|

3.0

|

2.0

|

0.26/0.3

|

|

Quarter stem ramp/door

|

150 τ

|

|---|---|

|

Side ramp/door

|

20 t

|

|

Ro-Ro equipment

|

Electrical Driven Type

|

|

ENERGY EFFICENCY PARTICULARS

|

|

|---|---|

|

Service speed @ Td

(NCR, Bft,0/DSS0. with 15% Sea Margin) |

19.0 knots

|

|

ECO speed @ Td

|

16.0 knots

|

|

Energy Saving Solutions

|

||||

|---|---|---|---|---|

|

* Twisted rudder + Fan Cap + Fan Duct

|

||||

|

* Self-polishing A/F paint

|

||||

|

* VFD control for cool. S.W. pumps, E/R vent, fans

|

||||

|

M/E Fuel Consumption @Td, NCR (15% S M. included)

|

||||

|---|---|---|---|---|

|

|

DF6C(t/d)

|

DFPC(t/d)

|

DFCOC(t/d)

|

|

|

Tier II

|

36.2

|

0.00

|

43.2

|

|

|

Tier III

|

37.2

|

0.00

|

44.3

|

|

|

(LCV LNG 50,000 kJ/kg. MGO 42,700 kJ/kg. , ISO cond., excl. tol)

|

||||

|

CLASSIFICATION

|

|

|---|---|

|

DNV

|

+ 1A, Car Carrier, Gas fuelled LNG, Fuel ready(Ammonia, D), MCDK, COAT-PSPC (B), E0, NAUT(OC), BIS, BWMC(T). DG(P), TMON(Oil lubricated), LCS, Recyclable, ER (EGR, Tier III), Shore power

|

|

EEDI

|

IMO Phase 2

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 274,0 m

|

|

Breadth, molded

|

48 m

|

|

Depth, molded:

|

23.6 m

|

|

Design draft, molded:

|

16.0 m

|

|

Scantling draft, molded:

|

17.2 m

|

|

Deadweight at Ts:

|

157K

|

|

Service speed:

|

14,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G70ME-C10.5 (Tier III)

|

|

MCR

|

13,340 kW at 66.6 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,300kW at 900 rpm

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 30 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.55 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

13,200 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Crude Oil

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 173,600 ㎥

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Available

|

|

SCRUBBER Fitted

|

|

|---|---|

|

Scubber System

|

U type, Open Loop

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 2,000 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

BWTS

|

4,000 m3/h

|

|

DECK CRANE

|

|

|---|---|

|

2 x Cargo hose handling crane

|

Each 20 MT

Personel Lifting Certified |

|

2 x Provisions handling crane

|

8 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Partially Coated / 2 x Epoxy anti-corrosive

|

|

WB tanks

|

Fully Coated / 2 x Epoxy anti-corrosive

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Mewis Duct and a twisted full spade rudder with bulb shall be installed for the improvement of propulsion efficiency

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE III

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 274,0 m

|

|

Breadth, molded

|

48 m

|

|

Depth, molded:

|

23.6 m

|

|

Design draft, molded:

|

16.0 m

|

|

Scantling draft, molded:

|

17.2 m

|

|

Deadweight at Ts:

|

157K

|

|

Service speed:

|

14,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G70ME-C10.5 (Tier III)

|

|

MCR

|

13,340 kW at 66.6 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,300kW at 900 rpm

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 30 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.55 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

13,200 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Crude Oil

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 173,600 ㎥

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Available

|

|

SCRUBBER Fitted

|

|

|---|---|

|

Scubber System

|

U type, Open Loop

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 2,000 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

BWTS

|

4,000 m3/h

|

|

DECK CRANE

|

|

|---|---|

|

2 x Cargo hose handling crane

|

Each 20 MT

Personel Lifting Certified |

|

2 x Provisions handling crane

|

8 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Partially Coated / 2 x Epoxy anti-corrosive

|

|

WB tanks

|

Fully Coated / 2 x Epoxy anti-corrosive

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Mewis Duct and a twisted full spade rudder with bulb shall be installed for the improvement of propulsion efficiency

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE III

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 274,0 m

|

|

Breadth, molded

|

48 m

|

|

Depth, molded:

|

23.6 m

|

|

Design draft, molded:

|

16.0 m

|

|

Scantling draft, molded:

|

17.2 m

|

|

Deadweight at Ts:

|

157K

|

|

Service speed:

|

14,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G70ME-C10.5 (Tier III)

|

|

MCR

|

13,340 kW at 66.6 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,300kW at 900 rpm

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 30 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.55 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

13,200 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Crude Oil

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 173,600 ㎥

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Available

|

|

SCRUBBER Fitted

|

|

|---|---|

|

Scubber System

|

U type, Open Loop

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 2,000 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

BWTS

|

4,000 m3/h

|

|

DECK CRANE

|

|

|---|---|

|

2 x Cargo hose handling crane

|

Each 20 MT

Personel Lifting Certified |

|

2 x Provisions handling crane

|

8 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Partially Coated / 2 x Epoxy anti-corrosive

|

|

WB tanks

|

Fully Coated / 2 x Epoxy anti-corrosive

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Mewis Duct and a twisted full spade rudder with bulb shall be installed for the improvement of propulsion efficiency

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE III

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

approx. 274,0 m

|

|

Breadth, molded

|

48 m

|

|

Depth, molded:

|

23.6 m

|

|

Design draft, molded:

|

16.0 m

|

|

Scantling draft, molded:

|

17.2 m

|

|

Deadweight at Ts:

|

157K

|

|

Service speed:

|

14,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

MAN B&W 6G70ME-C10.5 (Tier III)

|

|

MCR

|

13,340 kW at 66.6 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,300kW at 900 rpm

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Auxiliary boiler

|

Each 30 ton/h

|

|

Composite Boiler

|

1.5 ton/h (oil fired)

|

|

0.55 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

13,200 Nm3/h @ STP

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

Crude Oil

|

|

No. of cargo tanks

|

12 + 2

|

|

Cargo tanks capacity

|

approx. 173,600 ㎥

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Centrifugal, steam turbine driven

|

|

Cargo oil

|

3 x 3,000 ㎥/h x 130 mTH

|

|

Cargo heating

|

Available

|

|

SCRUBBER Fitted

|

|

|---|---|

|

Scubber System

|

U type, Open Loop

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 2,000 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

BWTS

|

4,000 m3/h

|

|

DECK CRANE

|

|

|---|---|

|

2 x Cargo hose handling crane

|

Each 20 MT

Personel Lifting Certified |

|

2 x Provisions handling crane

|

8 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo & Slop tanks

|

Partially Coated / 2 x Epoxy anti-corrosive

|

|

WB tanks

|

Fully Coated / 2 x Epoxy anti-corrosive

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

Mewis Duct and a twisted full spade rudder with bulb shall be installed for the improvement of propulsion efficiency

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF MOORING EQUIPMENT GUIDELINES [MEG4]

|

|

|

- ENERGY EFFICIENCY DESIGN INDEX [EEDI] PHASE III

|

|

|

- NOx TIER III

|

|

|

- ISGOTT 6

|

|

|

- STERN TUBE AIR SEALS

|

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

230 m

|

|

Breadth, molded

|

32.25 m

|

|

Depth, molded:

|

23.85 m

|

|

Design draft, molded:

|

11.75 m

|

|

Scantling draft, molded:

|

13.65 m

|

|

Deadweight @ Scantling Draft

|

51,641 MT

|

|

Service speed:

|

16,5 knots

|

|

MAIN ENGINE

|

|

|---|---|

|

Type

|

HYUNDAI-MAN B&W 6G60ME-C10.5-LGIP-HPSCR with EEC function

|

|

MCR

|

12,810 kW at 94,5 rpm

|

|

POWER GENERATORS

|

|

|---|---|

|

3 - DG

|

3 sets x 1,760 kWe each

|

|

BOILERS & I.G.G

|

|

|---|---|

|

Composite Boiler

|

3 ton/h (oil fired

|

|

0.85 ton/h (exhaust gas)

|

|

|

Inert Gas System

|

5,300 Nm3/h

|

|

CARGO CAPACITY

|

|

|---|---|

|

Cargoes:

|

* Commercial Butane (normal and iso-butane mixed in any proportion)

* Pure Propane * Commercial Propane (maximum 8.0 mole % ethane in the liquid phase) * Mixture of Propane and Butane in any proportion *Propylene *Anhydrous Ammonia |

|

No. of cargo tanks

|

Four (4)- No.4 cargo tank to be used as LPG fuel tank

|

|

Cargo tanks capacity

|

approx. 88,000 ㎥ (at 100%)

|

|

CARGO PUMPS

|

|

|---|---|

|

Type

|

Deepwell pumps of vertical, centrifugal, multistage design

|

|

Specification

|

8 x 600 ㎥/h

|

|

Booster Pumps

|

2 x 600 ㎥/h

|

|

BALLAST SYSTEM

|

|

|---|---|

|

Type

|

Centrifugal, electric motor driven

|

|

Capacity

|

2 x 650 m3/h x 35 mTH

|

|

BWTS

|

|

|---|---|

|

Hyundai HiBallast

|

Premium quality, non filter, 3,600 m3/h, IMO & USCG approved

|

|

DECK CRANE

|

|

|---|---|

|

1 x Hose handling crane

|

10 MT / Personel Lifting Certified

|

|

2 x Provisions handling crane

|

4 MT (P), 2 MT (S)

|

|

TANKS COATING PROTECTION

|

|

|---|---|

|

Cargo tanks insulation

|

Spray foam insulation with a polymeric surface protection coating

|

|

WB tanks

|

Full Epoxy

|

|

ENERGY SAVING DEVICE

|

|

|---|---|

|

IE2 high efficiency motors for essential pumps, Variable Frequency Drives for LP and HP LPG and main CSW pumps, Ultra Low Friction Biotechnology Antifouling, HD Hyundai ISS Intergated Smart Ship Solution, HiNAS Hyundai intelligent Navigation Assistant System, EEC Economizer Energy Control System

|

|

|

LATEST REQUIREMENTS & GUIDELINES COMPLIANT

|

|

|---|---|

|

- OCIMF Mooring Equipment Guidelines [MEG4]

|

|

|

- NOx TIER III

|

|

|

- Energy Efficiency Design Index [EEDI] PHASE III

|

|

|

- Stern Tube AIR SEALS

|

|

|

- CCTV system

|

|

|

KEY FEATURES

|

|

|---|---|

|

- NOx Tier II: M/E with EGR, A/E on gas mode & SCR * Adaptable for STS LNG bunkering

|

|

|

- Hull form features SDARI S-BOW - Optimized car flew efficiency

|

|

|

- BEVs and hydrogen-fueled vehicles (FCEVs) carded - IMDG packaged cargo on deck 5

|

|

|

- Shore connection for zero emission in port

|

|

MAIN PARTICULARS

|

|

|---|---|

|

Length Overall

|

abt. 199.90 m

|

|

Length between perp.

|

195.60 m

|

|

Breadth moulded

|

38.00 m

|

|

Depth moulded (to main deck)

|

14.80 m

|

|

Depth moulded (to upper deck)

|

abt. 36.58 m

|

|

Design draught (Td)

|

8.60 m

|

|

Scantling draught (Ts)

|

10.00 m

|

|

Air draught (from BWL)

|

max. 38.00 m

|

|

Deadweight Td

|

10.800 t

|

|

Deadweight @ Ts

|

18,500 t

|

|

Gross tonnage

|

69.000

|

|

Complement

|

25 P

|

|

TANK CAPACITIES

|

|

|---|---|

|

LNG {2 Type C tanks)

|

2x 1,650 m3

|

|

MGO

|

1.700 m3

|

|

Fresh/Drinktng wafer

|

460 m3

|

|

Water ballast

|

7000 m3

|

|

Endurance @ gas mode

19kn. ME+1xAE. fill. ratio 90%. LCV 50,000 kJ/kg. 5% reserve) |

12,500 n.m

|

|

Endurance @ diesel mode

(19kn, ME+1 xAE. fill. ratio 98%, LCV 42.700kJ/kg) |

11,500 n.m

|

|

MACHINERY MAIN COMPONENTS

|

|

|---|---|

|

Main engine

|

MAN 6S60ME-C10.5-GI-EcoEGR, Mk.2

|

|

NMCR

|

14.940 kW X 105 r/min

|

|

SMCR

|

13.300 kW x99 r/min

|

|

NCR

|

11.305 kWx 93.8 r/min

|

|

Propeller

|

1 X FPP

|

|

FGSS

|

High pressure type

|

|

DF generators

|

3 X 1,500 kWe

|

|

Bow thruster

|

1 X 1.800 kW, CPP

|

|

CARGO CAPACITY & EQUIPMENT

|

|

|---|---|

|

Car deck effective area

|

59,000 m2

|

|

Car capacity {Corona RT-43L)

|

approx. 7,000 CEU

|

|

No. of car decks

|

12

|

|

No. of liftable decks (DK 2.4. e. 8)

|

4

|

|

CAR DECK LOAD

|

||||

|---|---|---|---|---|

|

|

|

|

Med. deck

|

Light deck

|

|

Axle load

|

t/wheel No.

|

45/2, 55/4

|

5/2, 25/4

|

1.6/2

|

|

UDL

|

t/m2

|

3.0

|

2.0

|

0.26/0.3

|

|

Quarter stem ramp/door

|

150 τ

|

|---|---|

|

Side ramp/door

|

20 t

|

|

Ro-Ro equipment

|

Electrical Driven Type

|

|

ENERGY EFFICENCY PARTICULARS

|

|

|---|---|

|

Service speed @ Td

(NCR, Bft,0/DSS0. with 15% Sea Margin) |

19.0 knots

|

|

ECO speed @ Td

|

16.0 knots

|

|

Energy Saving Solutions

|

||||

|---|---|---|---|---|

|

* Twisted rudder + Fan Cap + Fan Duct

|

||||

|

* Self-polishing A/F paint

|